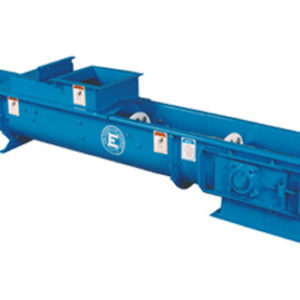

MAXI-TUFF AA Elevator Buckets – Maxi-Lift

The #1 selling plastic industrial bucket in North America.

The Maxi-Tuff AA centrifugal elevator bucket has the traditional shape of a cast iron bucket. This bucket has a heavy reinforced lip and corners with a thickened back wall for mounting strength. Standard spacing is projection x 2. The most common applications include handling stone, sand, gravel, coal, fertilizer, clay, salt, limestone and concrete. The Maxi-Tuff AA bucket is the best bucket for tough, abrasive industrial applications.

Description

Designed and Engineered for the toughest Industrial Applications

Features

- Reduces Weight on Elevator up to 80%

- Cleaner Discharge Than Steel Buckets

- Non-Corrosive, Non-Sparking

- Thicker Walls

- Heat, Impact & Abrasion Resistant

- Lowers Elevator Maintenance

- Reduces Energy Usage

- Extends Bucket Life

- Decreases Elevator Down Time

- Easy to Install and Replace

- Saves Money vs. Carbon Steel